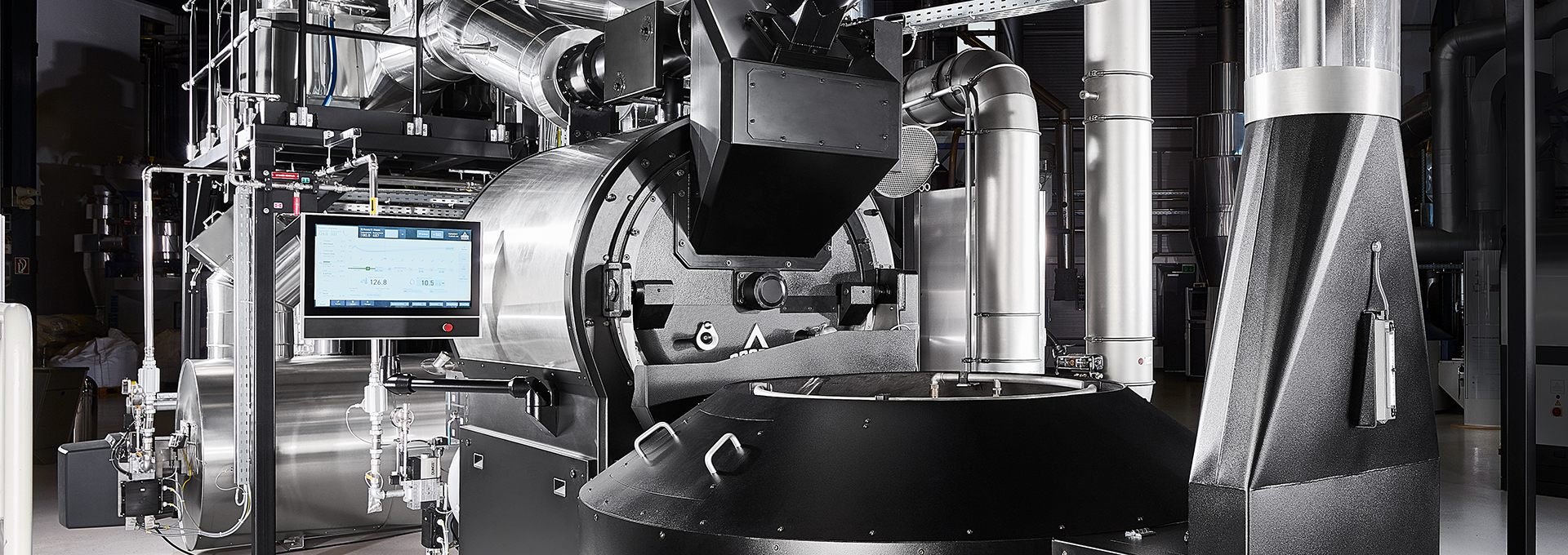

The Tangential Roasting Process

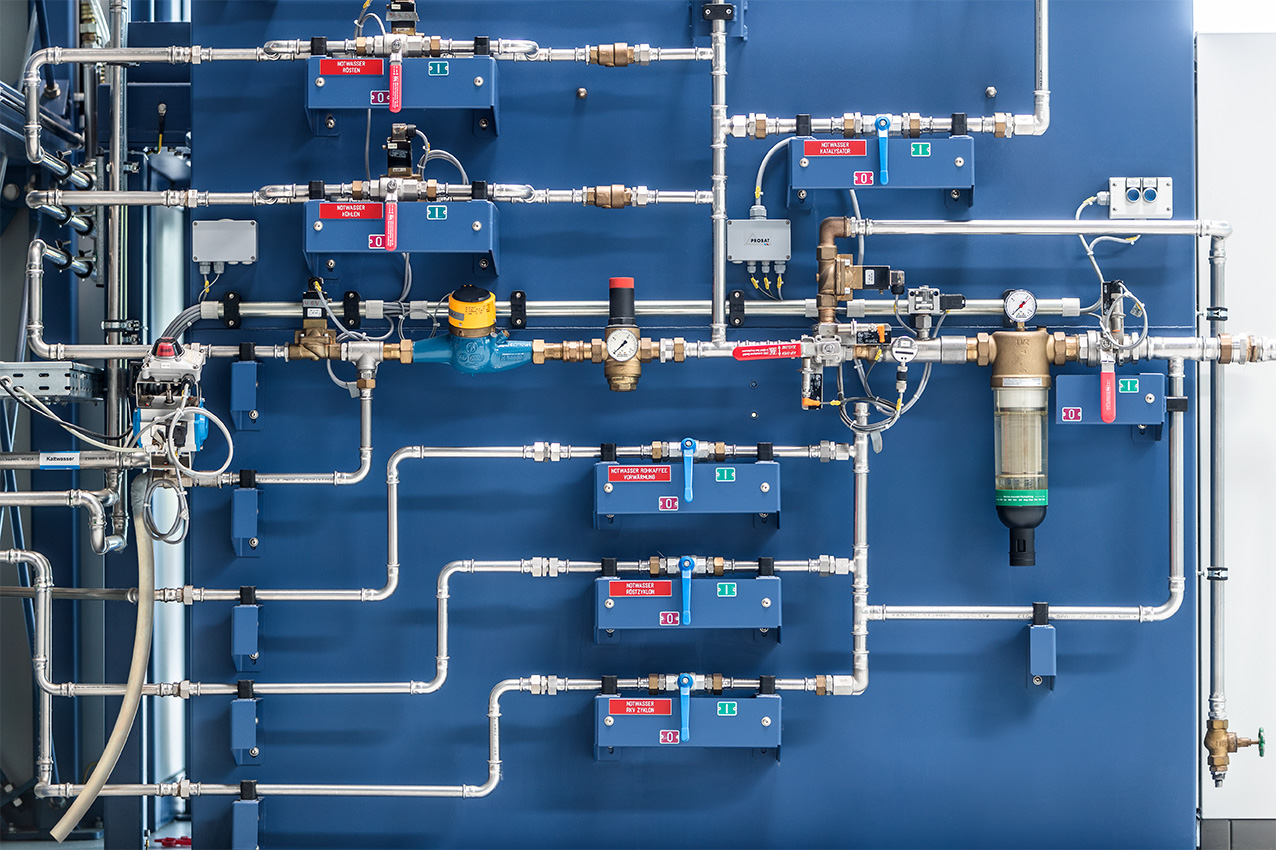

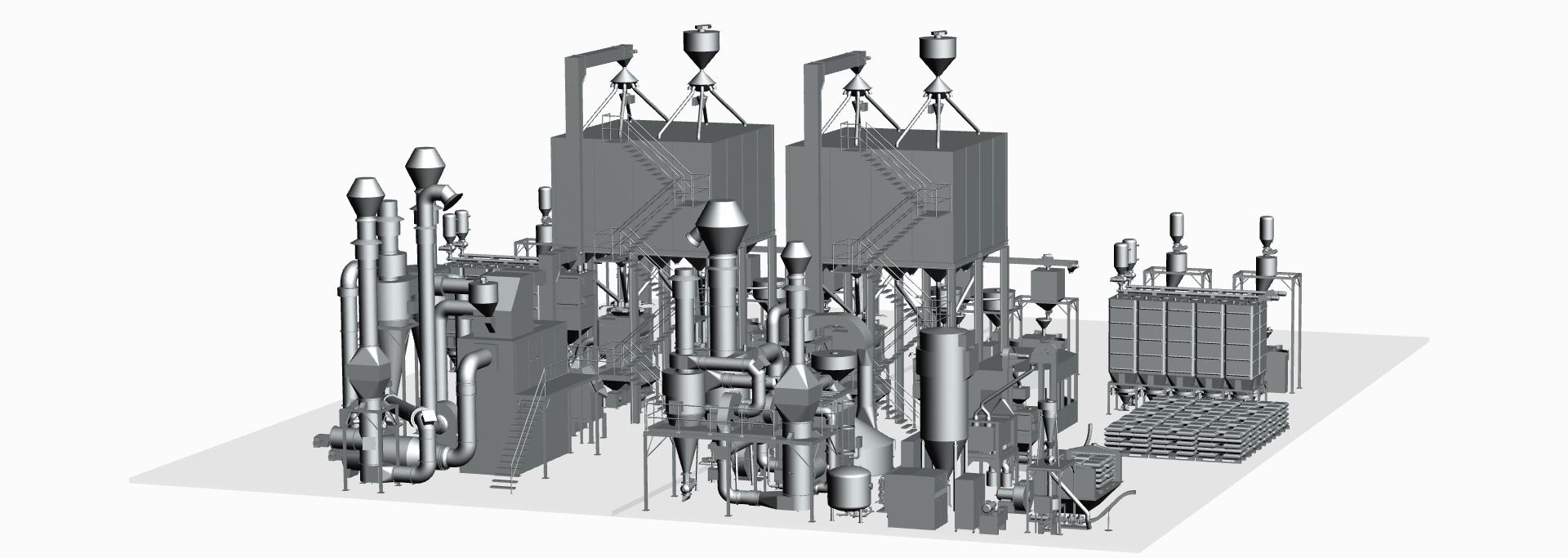

The heart of PROBAT’s JUPITER series tangential roaster is a closed and stationary roasting chamber. Specially developed, rotating shovels move and mix the coffee beans around the drum. The flow of hot incoming air transmits the heat onto the beans through convection. The combination of controlled roasting air and mechanically mixed coffee beans creates the perfect transition between the temperature of the bean’s surface and its core. The flow of incoming air can be reduced to a minimum without affecting the movement of the coffee. The addition of water systematically ends the roasting process while simultaneously precooling the roasted coffee.

Versions

Roasting time[min]

Roasting capacity[kg/h]

Batch size[kg]

Heating

JUPITER UII

Roasting time[min]

5,5-18

Roasting capacity[kg/h]

Up to 5.000

Batch size[kg]

50-780

Heating

natural gas, propane, hydrogen

JUPITER UIII

Roasting time[min]

3–18

Roasting capacity[kg/h]

Up to 4.000

Batch size[kg]

57–600

Heating

natural gas, propane, hydrogen

JUPITER SY

Roasting time[min]

1,5-18

Roasting capacity[kg/h]

Up to 3.000

Batch size[kg]

47-525

Heating

natural gas, propane, hydrogen

JUPITER HYBRID

Roasting time[min]

1,5-18

Roasting capacity[kg/h]

Up to 3.000

Batch size[kg]

47-600

Heating

natural gas, propane, hydrogen